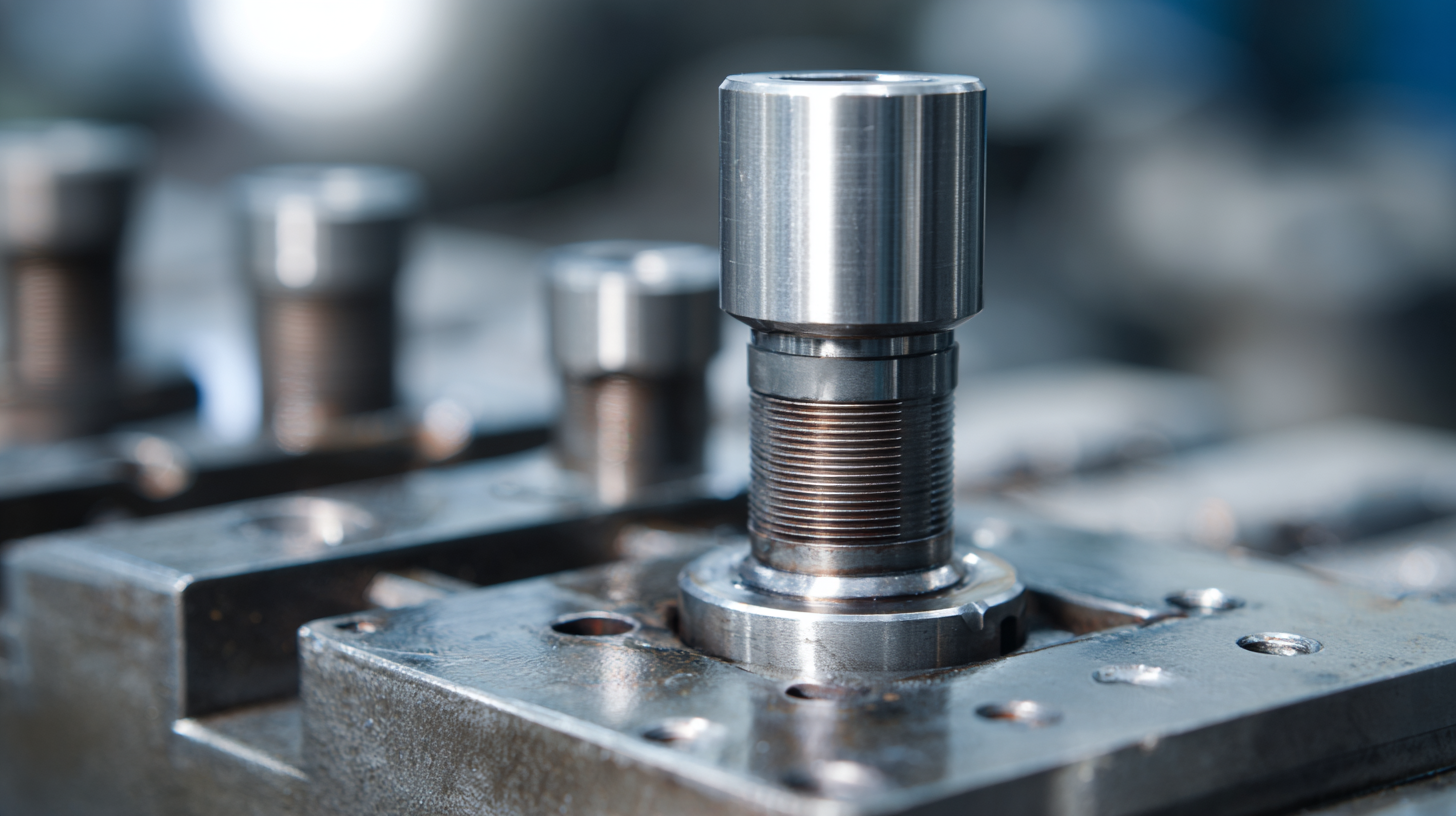

In the realm of precision engineering, the significance of thread gauges cannot be overstated. These essential tools play a pivotal role in ensuring that threaded components meet stringent industry standards, facilitating the seamless integration of parts across various applications. As industries increasingly focus on achieving impeccable accuracy and reliability, thread gauges have emerged as indispensable instruments for quality control and assurance. Their ability to accurately measure the size, pitch, and form of threads not only enhances manufacturing processes but also mitigates the risks of product failure and costly recalls. In this blog, we will delve into the real-world applications of the best thread gauges, exploring their impact on precision engineering and how they aid in meeting import and export certifications that are crucial for maintaining competitive standards in today's global market.

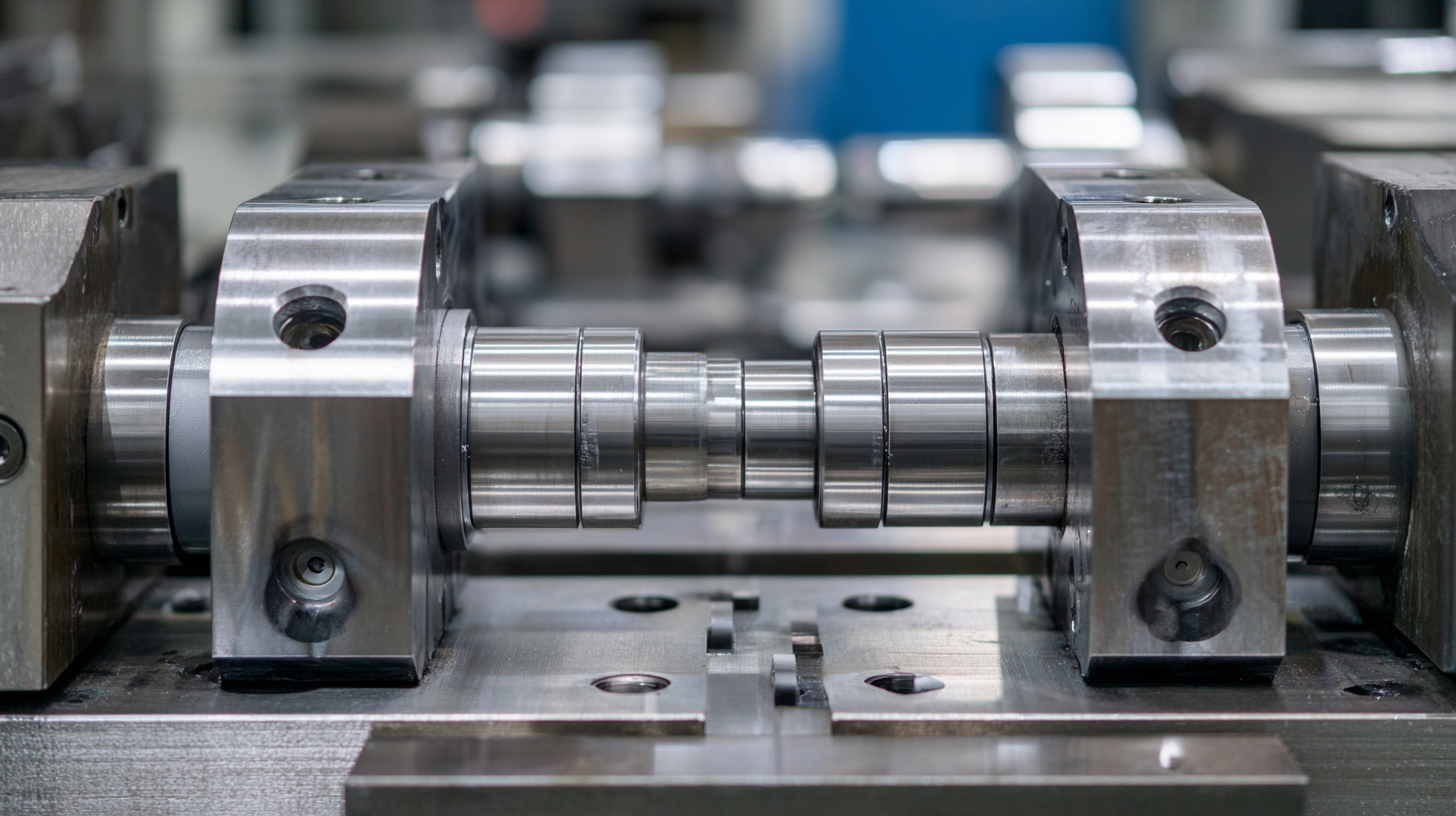

Thread gauges play a vital role in

precision engineering standards,

ensuring that threaded components fit together accurately and operate efficiently. These tools allow

engineers to verify the dimensions of threads, thus maintaining the integrity of mechanical assemblies.

In industries where precision is paramount, such as aerospace

and automotive manufacturing, the use of high-quality

thread gauges is non-negotiable. By adhering to standardized thread forms, manufacturers can minimize

the risk of failure and enhance the functionality of their products.

Thread gauges play a vital role in

precision engineering standards,

ensuring that threaded components fit together accurately and operate efficiently. These tools allow

engineers to verify the dimensions of threads, thus maintaining the integrity of mechanical assemblies.

In industries where precision is paramount, such as aerospace

and automotive manufacturing, the use of high-quality

thread gauges is non-negotiable. By adhering to standardized thread forms, manufacturers can minimize

the risk of failure and enhance the functionality of their products.

When selecting a thread gauge, consider the type of thread you’re working with, be it

Unified Thread Standard (UTS) or

Metric Thread Standard. Each application may require

gauges made from different materials, such as stainless steel or carbon steel, to match environmental

and operational conditions.

Tips: Always ensure that your gauges are calibrated

regularly to maintain accuracy. Additionally, when measuring threads, take multiple readings to account

for any inconsistencies, providing a comprehensive overview of the thread profile. Finally, choose

gauges that suit the specific application to optimize performance and durability in your

engineering projects.

In precision engineering, thread gauges play a crucial role in ensuring dimensional accuracy and quality control in manufacturing processes. There are several types of thread gauges available—such as go/no-go gauges, ring gauges, and plug gauges—each designed for specific applications. The go/no-go gauges help in quickly determining if a threaded part has acceptable dimensions, while ring and plug gauges can be employed to verify internal and external thread specifications, respectively. According to industry reports, effectively using calibrated thread gauges can reduce manufacturing errors by as much as 30%, leading to significant cost savings and enhanced product reliability.

Beyond traditional applications, the rise of virtual instrumentation is transforming the way engineering education and practical applications are approached. Recent studies reveal that incorporating virtual simulations, such as those for micrometers and thread gauges, allows students to understand measurement principles better while minimizing resource consumption. Moreover, the integration of advanced crimping tools in the manufacturing process highlights the importance of precise connections in electrical systems, which parallels the critical need for accurate thread measurements in mechanical assemblies. These developments emphasize the importance of selecting the right gauge for specific engineering tasks, ultimately enhancing precision and improving overall product quality.

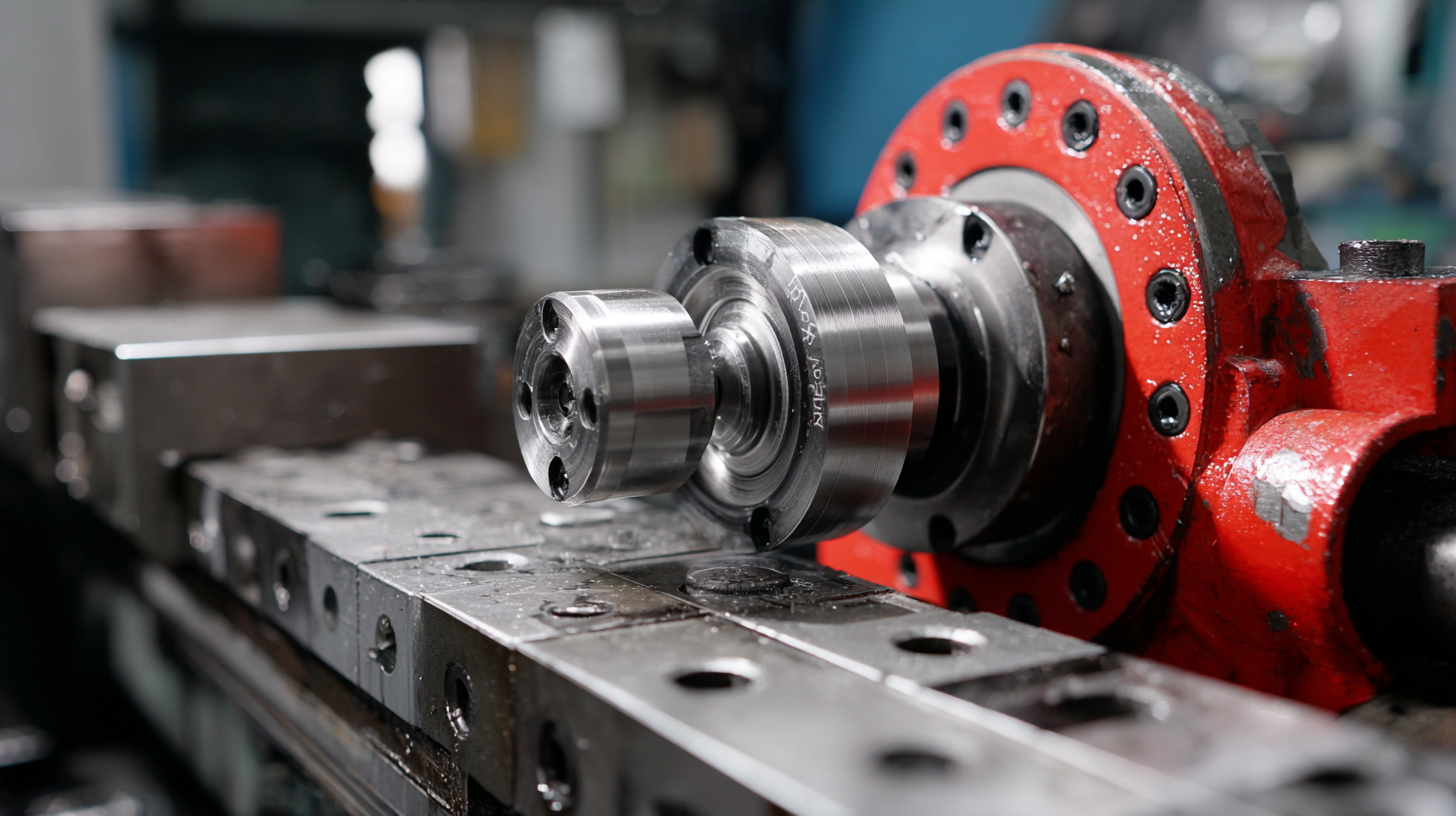

Thread gauges play a pivotal role in enhancing manufacturing efficiency and quality by ensuring precise measurements in production processes. Their accuracy is crucial in various applications, from automotive to aerospace, where even the slightest deviation can lead to costly errors. By implementing the best thread gauges, manufacturers can achieve tighter tolerances, reduce waste, and thereby streamline operations.

To maximize the benefits of thread gauges, consider these tips: First, invest in high-quality gauges tailored to your specific application. This will not only improve measurement accuracy but also extend the lifespan of your tools. Second, ensure regular calibration and maintenance of gauges to avoid inaccuracies that could compromise production quality. Finally, train employees on the proper use and handling of these gauges to foster a culture of quality awareness within the organization.

By integrating advanced thread gauges into manufacturing processes, companies can enhance their overall productivity and foster a commitment to quality. As industries continue to innovate, the reliance on such precise tools will become increasingly important for maintaining competitive advantage.

| Application Area | Type of Thread Gauge | Precision Level | Impact on Manufacturing |

|---|---|---|---|

| Aerospace | Go/No-Go Gauges | High Precision | Ensures safety and reliability of components |

| Automotive | Thread Plug Gauges | Medium Precision | Improves assembly accuracy and reduces rework |

| Electronics | Thread Ring Gauges | High Precision | Essential for ensuring connection integrity |

| Manufacturing | Combined Gauges | Standard Precision | Optimizes production processes and reduces waste |

| Oil & Gas | Specialty Thread Gauges | Very High Precision | Critical for preventing leaks and ensuring equipment longevity |

In various industries, the accuracy of threaded components is critical for ensuring the integrity and safety of the overall system. For instance, in the aerospace sector, where components are subject to extreme conditions and high stresses, the use of precision thread gauges ensures that screws and fittings meet stringent specifications. This helps prevent failures that could lead to catastrophic incidents, highlighting the essential role of thread gauges in maintaining safety standards.

In automotive manufacturing, thread gauges enhance the assembly process by streamlining quality control. Manufacturers employ both go/no-go gauges to quickly verify that threaded parts conform to required tolerances, thus reducing the risk of operational issues in the final vehicle. The precision offered by these tools ultimately leads to increased reliability and performance in vehicles, demonstrating their impact on both safety and customer satisfaction. By incorporating best practices in thread gauging, industries can optimize their operations, reduce costs, and improve product quality significantly.

As the landscape of precision engineering evolves, so too does the technology surrounding thread gauges. Future trends indicate a shift towards more advanced materials and digital technology integration. High-performance polymers and composite materials are becoming increasingly popular in the production of thread gauges, providing durability and resistance to wear without compromising accuracy. These materials not only enhance the lifespan of gauges but also enable engineers to utilize them in demanding environments, ensuring consistent performance.

Moreover, the incorporation of smart technology is revolutionizing the way thread gauges are utilized in manufacturing processes. The rise of IoT (Internet of Things) devices allows for real-time monitoring and data collection, leading to a streamlined measurement process. Engineers can now receive immediate feedback on thread dimensions and tolerances, facilitating quicker adjustments and reducing the margin of error. This shift towards automation and connectivity signifies a promising future for thread gauge technology, driving the efficiency and accuracy of precision engineering to unprecedented levels.

This chart illustrates the real-world applications of thread gauges across different industries, demonstrating their significance in enhancing precision engineering. The automotive industry leads with 25% usage, while electronics follows with 10%. Understanding these trends helps in future innovations of thread gauge technologies and engineering solutions.