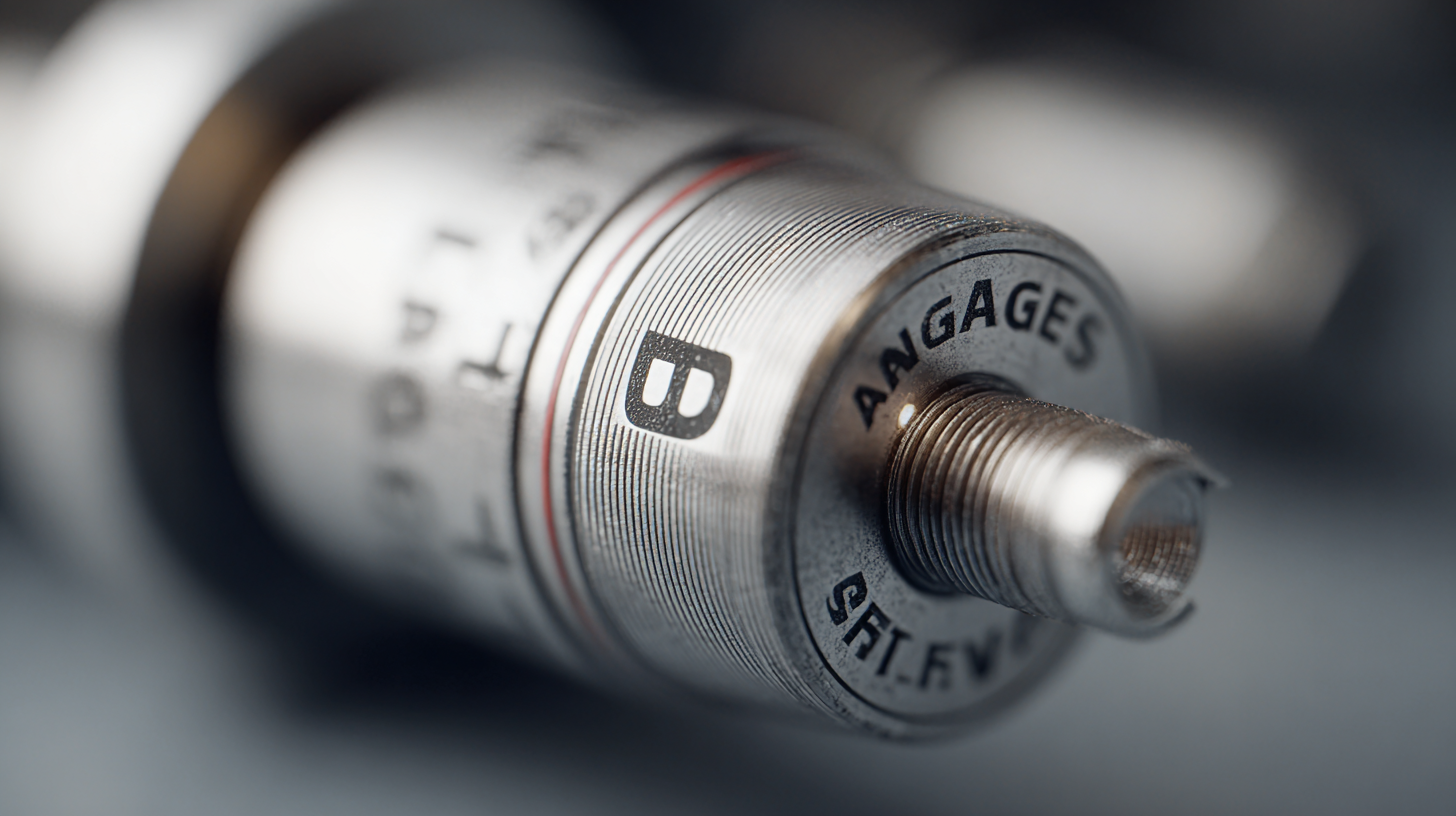

In the realm of precision manufacturing, the significance of thread gauges cannot be overstated, as they serve as critical tools for ensuring that threaded components meet the stringent specifications required for optimal performance. Understanding industry standards is essential for manufacturers seeking to enhance the quality and reliability of their products.

This blog will explore the top thread gauge types, delving into the characteristics that define their effectiveness and accuracy. By examining the best practices associated with their use, we aim to provide insights that empower manufacturers to make informed decisions regarding their thread gauge selection.

As industry technologies evolve and manufacturing processes become increasingly complex, staying abreast of the latest standards not only enhances product quality but also drives operational efficiency. Join us as we navigate the essential aspects of thread gauges and their pivotal role in the precision manufacturing landscape.

This blog will explore the top thread gauge types, delving into the characteristics that define their effectiveness and accuracy. By examining the best practices associated with their use, we aim to provide insights that empower manufacturers to make informed decisions regarding their thread gauge selection.

As industry technologies evolve and manufacturing processes become increasingly complex, staying abreast of the latest standards not only enhances product quality but also drives operational efficiency. Join us as we navigate the essential aspects of thread gauges and their pivotal role in the precision manufacturing landscape.

In precision manufacturing, the significance of thread gauges cannot be overstated. These tools play a pivotal role in ensuring the integrity and accuracy of threaded components, which are critical in applications ranging from aerospace to automotive. As manufacturers strive for higher quality and consistency, utilizing high-caliber thread gauges ensures that all threaded parts meet stringent specifications. This is particularly important in industries where even the slightest deviation can compromise safety and performance.

Moreover, the integration of advanced metrology technologies is transforming how precision is achieved in manufacturing. Businesses are increasingly recognizing the need for comprehensive calibration methods to maintain the reliability of their measuring instruments, including handheld gauges. Regular maintenance and understanding the geometry of threaded components can enhance the overall efficiency and manufacturing process, ensuring that products meet the evolving demands of the industry. With a focus on precision, manufacturers are better equipped to innovate and compete in today's fast-paced marketplace.

In precision manufacturing, understanding the key industry standards for thread gauges is paramount for ensuring quality and accuracy in production. Some of the most recognized standards include the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). According to a recent report by the American Society of Mechanical Engineers (ASME), about 70% of industrial manufacturers rely on these standards to maintain compliance and improve product consistency. Ensuring your thread gauges conform to these standards not only enhances the reliability of measurements but also reduces the risk of costly errors in manufacturing processes.

When selecting thread gauges, consider investing in those that meet ISO 1502 specifications, which outlines the requirements for the dimensions and tolerances of gauges. These guidelines are crucial for industries such as aerospace and automotive, where precision is non-negotiable. Incorporating best practices by regularly calibrating your thread gauges can significantly improve measurement accuracy—experts recommend calibration every six months or more frequently if used in high-precision environments.

Tips: Always keep track of your gauge's calibration history; this will help you maintain compliance with industry standards. Additionally, utilize gauge blocks during setup to verify the accuracy of your thread measuring tools before production runs, ensuring optimal performance and reduced downtime.

When it comes to precision manufacturing, selecting the right type of thread gauge is essential for ensuring product quality and accuracy. Different applications may require specific thread characteristics; thus, it's crucial to understand the options available. For example, plug gauges are perfect for checking internal threads, while ring gauges are more suitable for external threads. Always consider the thread standards applicable to your industry, as these will dictate the type of gauge that should be used.

**Tips:** When choosing a thread gauge, first evaluate the specific needs of your manufacturing process. Look into the materials you’ll be working with and the expected tolerances. A good practice is to have a range of gauges that cater to various thread sizes and pitches to ensure versatility across different projects. Additionally, consider investing in digital gauges, which can provide more precise measurements and easier readability.

Another tip is to regularly calibrate and maintain your gauges to ensure long-term reliability. Gauges that are out of specification can lead to quality control issues, negatively impacting production efficiency. Establish a routine for checking gauge calibration against standards, and keep a log for future reference. This diligence not only enhances the accuracy of your manufacturing processes but also fosters a culture of quality.

In precision manufacturing, maintaining the accuracy of thread gauges is paramount to ensuring product quality and operational efficiency. According to a recent report by the National Institute of Standards and Technology (NIST), inaccuracies in measurement can lead to a 10-20% increase in manufacturing costs due to rework and scrap. Therefore, adopting best practices for thread gauge calibration is essential. This involves regular and meticulous calibration schedules, using equipment that meets industry standards, and employing qualified personnel to perform the calibrations.

One effective strategy is to implement a traceable calibration regime where each gauge is measured against certified reference standards. A study published in the Journal of Manufacturing Science and Engineering highlights that organizations that adopt this approach report a 15% improvement in measurement consistency. Additionally, utilizing calibration tools and practices compliant with ISO 17025 can minimize variability in process outputs. By prioritizing these best practices, manufacturers not only enhance precision but also optimize their quality assurance processes, ultimately leading to a more reliable production environment.

This bar chart represents the average calibration accuracy percentages of different types of thread gauges used in precision manufacturing. The data showcases the effectiveness of various calibration practices over a period of time.

As precision manufacturing continues to evolve, thread gauging technology is experiencing significant advancements that promise to transform industry standards. One of the most notable future trends is the integration of smart technology into thread gauging processes. This includes the use of IoT-enabled gauges that can collect real-time data and offer immediate feedback to operators. Such innovations not only enhance measurement accuracy but also streamline production processes, reducing wastage and improving overall efficiency.

Another crucial development is the emphasis on automation in thread gauging. With the rise of automated machining systems, thread gauges that function seamlessly with robotic arms are becoming essential. These automated systems can perform high-volume inspections consistently, providing manufacturers with quick turnaround times while maintaining the highest quality standards. Furthermore, as industries push towards sustainability, future thread gauging standards will likely focus on reducing environmental impact through the use of eco-friendly materials and energy-efficient designs, marking a significant shift in manufacturing practices.