As the manufacturing landscape evolves, the importance of precision tools like thread taps has become increasingly evident. By 2025, the global manufacturing market is projected to reach $12 trillion, with significant contributions from cutting-edge technologies and materials. According to a report by MarketsandMarkets, the tool and die industry is expected to experience a compound annual growth rate (CAGR) of 5.4%, highlighting an upward trend in demand for high-quality tools, including thread taps. These tools are critical for creating durable and accurate threads in various materials, making them essential in automotive, aerospace, and industrial applications.

As manufacturers embrace automation and Industry 4.0 technologies, developing best practices in thread tap strategies will be pivotal to maintaining quality and efficiency in production processes. Emphasizing innovation in thread tap design and materials could set the stage for global competitiveness, especially for leading manufacturing nations like China, which continues to assert its dominance in the global manufacturing sector.

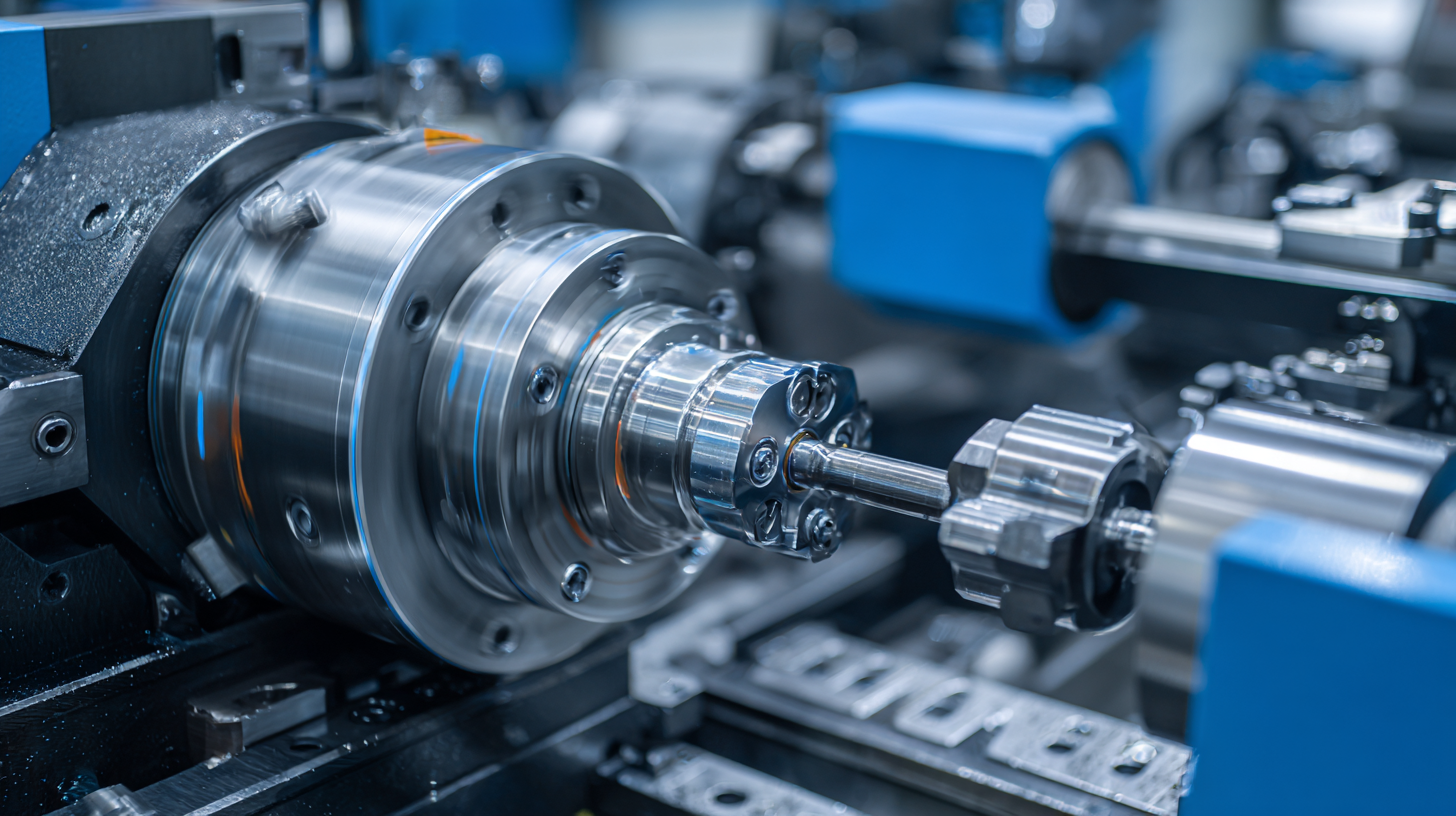

When it comes to optimizing manufacturing processes, selecting the right

thread tap suppliers is crucial.

Quality thread taps not only enhance efficiency but also ensure durability

and precision in production. Therefore, it's essential to identify key

characteristics that distinguish high-caliber suppliers from the rest.

First and foremost, a reputable thread tap supplier should possess a proven

track record in the industry. This includes certifications and compliance

with international quality standards, which indicate a commitment to

excellence.

Additionally, a focus on innovation and

technology is vital; suppliers who invest in advanced manufacturing

techniques and research are likely to provide superior products that meet

the evolving demands of the market.

Another important characteristic is customer support and service. Quality suppliers

offer comprehensive technical support,

ensuring that clients receive guidance on the best threading solutions for their

specific applications. They should also provide an extensive range of products,

catering to different materials and threading needs, which allows manufacturers to

maintain flexibility in their operations. By focusing on these key attributes,

manufacturers can forge partnerships with thread tap suppliers that drive

efficiency and quality

in their production lines.

Another important characteristic is customer support and service. Quality suppliers

offer comprehensive technical support,

ensuring that clients receive guidance on the best threading solutions for their

specific applications. They should also provide an extensive range of products,

catering to different materials and threading needs, which allows manufacturers to

maintain flexibility in their operations. By focusing on these key attributes,

manufacturers can forge partnerships with thread tap suppliers that drive

efficiency and quality

in their production lines.

As the manufacturing landscape evolves, evaluating supplier performance becomes crucial to maintain competitive advantage. According to a report by McKinsey, companies that rigorously assess their suppliers can improve their operational efficiency by up to 20%. Key metrics to consider include on-time delivery rates, quality defect rates, and cost performance. By focusing on these metrics, manufacturers can establish a robust supplier evaluation framework that not only the ideal partners but also drives continuous improvement.

Incorporating advanced analytics into supplier performance evaluation can significantly enhance decision-making. A study from Deloitte found that 65% of manufacturers using data analytics to track supplier performance experienced fewer disruptions in their supply chain. Metrics such as lead times and inventory accuracy should be analyzed to ensure that suppliers align with production schedules effectively. By leveraging these strategies, manufacturers can navigate the complexities of future trends and ensure that their supply chains remain resilient and responsive to market demands.

Building strong relationships with thread tap suppliers is crucial for manufacturers looking to enhance their production capabilities as they navigate the rapidly evolving landscape of the industry. Establishing clear communication from the outset is essential. This means discussing technical specifications, lead times, and quality expectations openly. By fostering an environment of transparency, manufacturers can align their goals with suppliers, enabling them to work collaboratively to solve issues as they arise.

Additionally, investing in long-term partnerships can yield significant benefits. Regularly engaging with suppliers through feedback sessions can improve the product offerings and ensure that the thread taps supplied meet evolving market demands. Understanding the suppliers' capabilities and constraints is key to managing expectations and encouraging innovation. By treating suppliers as true partners, manufacturers can leverage their expertise and gain insights that can drive efficiencies, ultimately enhancing competitiveness in the manufacturing sector as it heads toward 2025 and beyond.

As we move towards 2025, the landscape of global supply chains is evolving rapidly, presenting both opportunities and challenges for manufacturers. The interconnectedness of markets has enabled businesses to source materials and components from various parts of the world, driving efficiencies and cost savings. However, this increased reliance on global supply networks also exposes manufacturers to potential disruptions, such as geopolitical tensions, natural disasters, and shifting trade policies. Navigating these complexities requires innovative strategies and robust contingency planning.

To capitalize on the opportunities within global supply chains, manufacturers must invest in technology that enhances visibility and collaboration among supply chain partners. The adoption of advanced analytics and real-time data tracking can provide insights into supply chain performance, enabling companies to respond swiftly to changes and optimize their operations. Additionally, fostering relationships with local suppliers can reduce dependency on distant resources and mitigate risks associated with prolonged transportation times. By embracing these best practices, manufacturers can position themselves to thrive in an increasingly dynamic global market.

| Trend | Description | Opportunities | Challenges |

|---|---|---|---|

| Automation and AI | Increased use of robots and AI in manufacturing processes. | Enhanced efficiency and reduced labor costs. | High initial investment and skilled labor shortages. |

| Sustainability | Focus on eco-friendly manufacturing processes and materials. | Building a positive brand image and attracting eco-conscious consumers. | Possible higher costs and supply chain complexity. |

| Customization | Increased demand for personalized products. | Higher customer satisfaction and loyalty. | Challenges in production efficiency and cost management. |

| Supply Chain Transparency | Emphasis on understanding and tracking the supply chain. | Improved risk management and supplier relations. | Complexity in data integration and compliance. |

| Digital Twins | Creating virtual replicas of physical systems for analysis. | Enhanced predictive maintenance and optimized operations. | High implementation costs and technological learning curve. |

In today's rapidly evolving manufacturing landscape, the selection of suppliers has become increasingly critical to enhancing operational efficiency and fostering innovation. Innovative technologies are essential for optimizing the supplier selection process and ensuring long-term sustainability. For instance, the integration of artificial intelligence (AI) can significantly improve decision-making by analyzing vast amounts of supplier data, enabling manufacturers to select partners that align with their sustainability goals and business strategies.

**Tip:** Leverage AI tools to analyze supplier performance metrics and assess their adherence to sustainable practices. This can aid in pinpointing potential suppliers who not only meet quality standards but also contribute positively to the supply chain’s environmental impact.

Moreover, embracing advancements like blockchain technology can enhance transparency across the supply chain. This ensures that the selected suppliers are compliant with ethical standards and sustainability practices, thereby reducing risks associated with supply chain disruptions.

**Tip:** Implement blockchain solutions to create a transparent and traceable supplier network, which not only builds trust but also enhances collaboration among all stakeholders involved in the supply chain. This innovation can ultimately lead to improved supplier relationships and better alignment with corporate sustainability objectives.