In the manufacturing industry, precision is paramount, and the choice of tools can significantly influence product quality and operational efficiency. Thread gauges, integral to ensuring precise measurements of threads, play a crucial role in maintaining the standards of production across various sectors. According to a report by Grand View Research, the global manufacturing tools market is projected to reach $135 billion by 2025, highlighting the increasing focus on quality and accuracy in manufacturing processes. Utilizing high-quality thread gauges not only minimizes errors in threaded components but also enhances the overall reliability of products. As manufacturers strive to meet stringent quality assurance standards, investing in the best thread gauges becomes essential for achieving optimal performance, reducing waste, and ultimately driving profitability.

This blog discusses seven compelling reasons that underline the importance of selecting the finest thread gauges for your manufacturing needs, ensuring that your operations remain competitive and efficient.

In the realm of manufacturing, precision is not just a goal; it is a necessity. The use of high-quality thread gauges plays a critical role in achieving this precision. According to a report by the National Institute of Standards and Technology (NIST), approximately 30% of all manufacturing defects stem from incorrect measurements. This statistic underscores the importance of utilizing the best thread gauges to ensure that components meet their specified tolerances and function as intended. When manufacturers invest in top-notch equipment, they significantly reduce the risk of costly errors and enhance the overall quality of their products.

Moreover, precision in manufacturing can directly impact a company’s bottom line. A study published in the Journal of Manufacturing Science and Engineering found that improving measurement accuracy by just 1% can increase productivity by up to 3%. This is particularly crucial in industries such as automotive and aerospace, where even minuscule deviations can lead to catastrophic failures. By choosing the best thread gauges, manufacturers can not only improve their operational efficiency but also gain a competitive edge in an increasingly demanding market. The integration of precise measurement tools into production processes ultimately fosters innovation and drives sustainable growth.

Thread gauges play a critical role in ensuring product quality in manufacturing. These precision tools are essential for verifying the dimensions and tolerances of threaded components, which are fundamental in various industries, from automotive to aerospace. By utilizing the best thread gauges, manufacturers can accurately assess whether their products meet the required specifications, preventing defects that could lead to costly rework or product failures.

In addition to enhancing quality control, thread gauges significantly contribute to reducing waste. When manufacturers employ high-quality gauges, they can identify discrepancies early in the production process, minimizing scrap and re-manufacturing costs. This not only aids in maintaining a lean production line but also aligns with sustainable practices by reducing excess material usage. Ultimately, the use of the best thread gauges not only protects a company’s reputation by ensuring reliable products but also promotes a more efficient manufacturing process.

When selecting the best thread gauges for your manufacturing needs, certain key features play a crucial role in ensuring accuracy and efficiency. One of the most important aspects to consider is the material and construction of the gauge. High-quality materials, such as stainless steel, provide durability and resistance to wear and corrosion, enabling the gauges to maintain precision over time.

Additionally, a robust construction design that minimizes flexing or distortion during use will contribute significantly to the gauge’s longevity and reliability.

Another vital feature to look for is the measurement range and granularity. A good thread gauge should offer a wide range of sizes to accommodate various thread specifications. Moreover, gauges with marked increments can enhance ease of use and reduce the potential for errors when measuring threads. Lastly, consider the calibration methods available.

Thread gauges that come with certified calibration or easy recalibration options ensure that you maintain accuracy, crucial for meeting high manufacturing standards. By focusing on these key features, you can select the best thread gauges to meet the specific requirements of your production processes.

The thread gauge industry has undergone significant transformation thanks to innovative materials and advanced technologies. Traditional metal gauges are gradually being augmented or replaced by high-performance ceramics and composites that offer greater wear resistance and reduced weight. These modern materials not only enhance precision but also improve the longevity of the gauges, making them a cost-effective choice for manufacturers aiming to optimize production efficiency. Furthermore, the use of advanced coatings and surface treatments enhances corrosion resistance, ensuring that the gauges maintain their accuracy over extended periods, even in challenging environments.

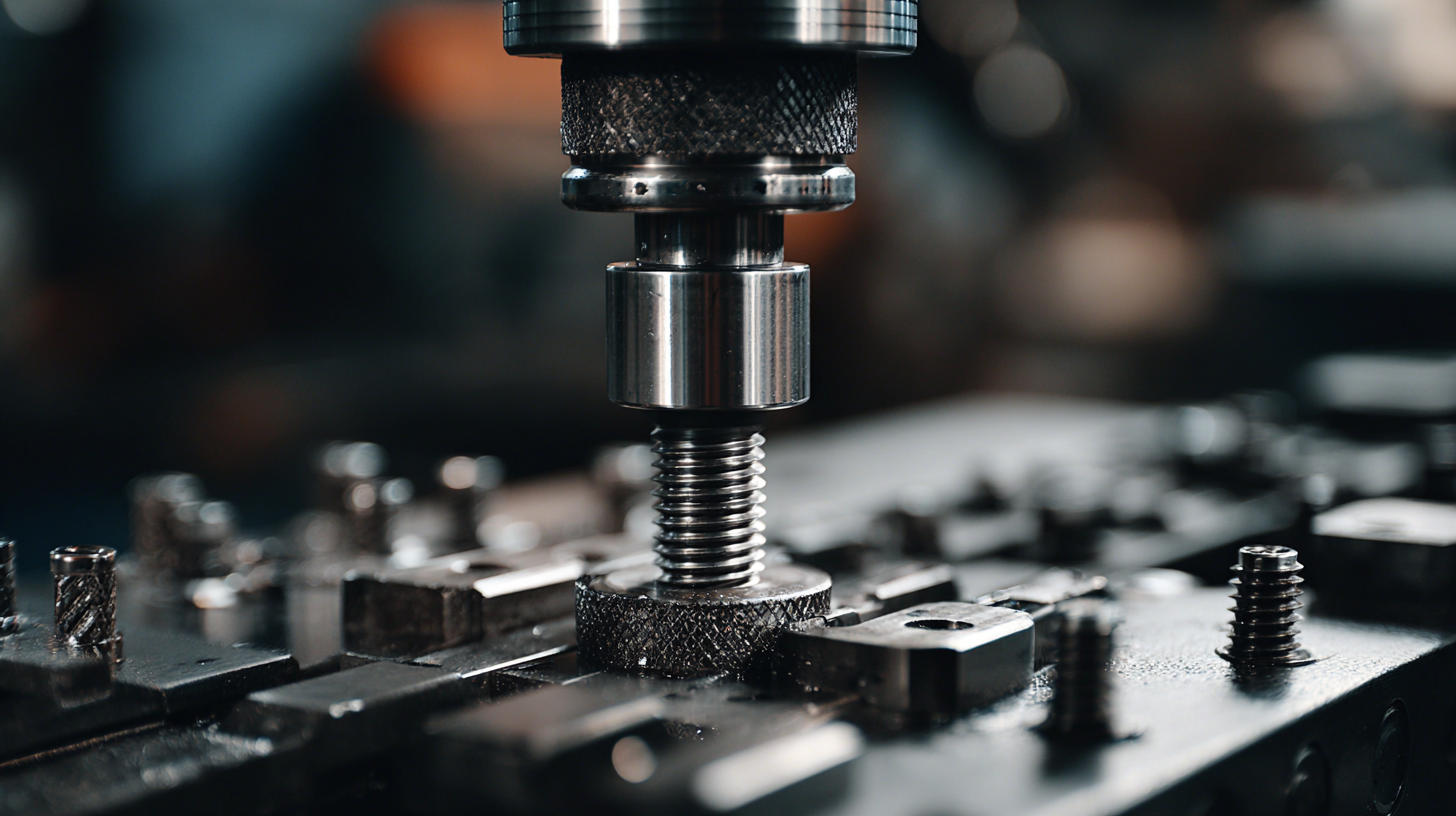

In parallel, advancements in manufacturing techniques, such as 3D printing and precision CNC machining, have revolutionized thread gauge design. These technologies allow for more complex geometries that cater to specialized applications while maintaining strict tolerances. The ability to quickly prototype and produce customized gauges enables manufacturers to respond dynamically to shifting market demands, ensuring they always have the tools needed for optimal quality control. By investing in modern thread gauges designed with innovative materials and techniques, manufacturers can secure not only better accuracy but also a competitive edge in the fast-paced manufacturing landscape.

As manufacturing evolves, the demand for precision and efficiency in production processes is more critical than ever. Future trends in measuring tools, particularly thread gauges, are poised to revolutionize how manufacturers ensure quality and maintain production standards. With advancements in technology, such as digital gauging and IoT integration, manufacturers can expect improved accuracy and real-time data, facilitating quicker decision-making and minimizing wastage.

Tip: Regularly invest in training for your team on the latest measuring tools and technologies. Familiarity with new devices can enhance their effectiveness and reduce the likelihood of errors.

Moreover, automation in measuring tools is becoming increasingly prevalent. Automated thread gauges can perform checks faster than manual methods, allowing operators to focus on more complex tasks that require human intervention. This shift not only streamlines the production process but also enhances overall productivity, contributing significantly to efficiency gains.

Tip: Schedule routine calibration and maintenance of your thread gauges to ensure they perform at optimal levels and continue to meet industry standards. Proper upkeep can extend the lifespan of your tools and improve accuracy.

| Reason | Impact on Manufacturing Efficiency | Future Trends |

|---|---|---|

| Precision Measurement | Enhances quality control and reduces waste. | Rise of smart manufacturing technologies. |

| Durability | Longer tool life minimizes replacement costs. | Focus on sustainable materials and practices. |

| Versatility | Compatible with a range of applications enhances productivity. | Integration with multiple systems and environments. |

| User-Friendly Design | Simplifies training and operator error reduction. | Emergence of ergonomic designs and interfaces. |

| Cost-Effectiveness | Reduces operational costs while maintaining quality. | Adoption of advanced manufacturing techniques. |

| Compliance with Standards | Ensures adherence to industry regulations and safety standards. | Increasing regulations driving innovation in tools. |

| Innovative Technology | Enhances measuring accuracy and speed. | Growing role of AI and IoT in manufacturing tools. |